If you have one of these Sony clocks (ICF-C1), you may find the time base isn't very accurate. My clock was running fast - gaining about 2 minutes per month. Other clocks of the same type might be more accurate - maybe just the luck of the draw in my case.

Some clock radios use the power line frequency as a time base. Power utilities adjust the total number of cycles each day to keep clocks accurate day to day.

The ICF-C1 on the other hand uses a 32.768KHz crystal as the time base. The advantage of a crystal time base is the ability to keep running via a battery during a power failure. When the power is restored, the clock comes back to life with the correct time. But a crystal's frequency is subject to manufacturing tolerance as well as load capacitance tolerance.

For an average month of 30 days, the frequency deviation is calculated as follows:

The crystal would need a frequency deviation of approximately 1.517 Hz to gain 2 minutes in a month. This would result in a frequency of approximately 32,769.517 Hz. A typical 32.768KHz crystal frequency tolerance is around 20ppm (+/- 0.655Hz). Load capacitor variations can account for an additional 100ppm (+/- 3.268Hz). The combined factors would easily account for the 2 minutes per month gain in my clock, roughly 46ppm total.

Unfortunately, the Sony clock does not provide a mechanism to make time base adjustments, such as an adjustable capacitor in place of one of the fixed value load capacitors. And unless you have access to a quality frequency counter, frequency adjustment would be a tedious trial and error process even if an adjustment were provided.

If you want to upgrade the clock time base and dispense with the adjustment procedure, you can replace the crystal with a calibrated clock source. This is the approach I took.

Project Approach

I was not able to find a service manual for the ICF-C1 so I had to do some reverse engineering. A search for "ICF-C1" on iFixit came up with instructions on how to open the case. The majority of the clock circuitry is based on a microcontroller (MCU). The MCU is stamped 87BB08A but I was not able to find the datasheet (I think the full part number is LC87BB08A). I did find a service manual for an ICF-C128 clock, and while that is a different clock, the schematic shows it uses an LC872B06A MCU that has the same connections as the MCU in the ICF-C1. All we need to know is which of the pins XT1 or XT2 is the Clock Input.

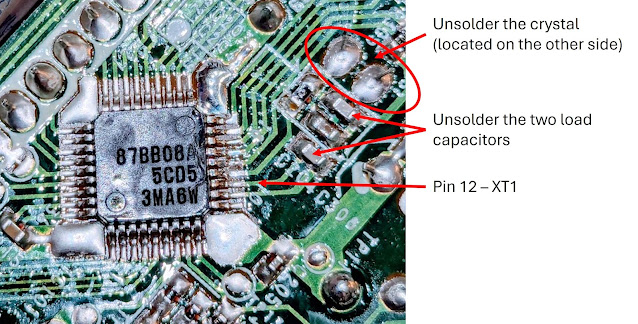

The LC87 MCU family designates XT1 as the clock input pin, and on our MCU, that is pin 12. To change the clock source, all we need to do is remove the 32.768KHz crystal and two associated capacitors and then feed a 32.768KHz signal from an accurate time base into Pin 12.

Analog Devices DS32KHZS

The time base component I chose is the DS32KHZS#. This part generates a 32.768KHz signal that is accurate to +/- 2ppm (0C to 40C) or ~1 minute per year! That seems pretty good. These chips are expensive so it is understandable why Sony didn't go this route.

A nice feature of the DS32KHZS is that it contains support circuitry for connections to a backup battery. The Sony clock has a backup battery in place, so we can tap into that. Just four connections are needed: power, ground, battery and signal into the MCU.

Time Base Install

I chose to make a small carrier board for the DS32KHZ. I used toner transfer to make the board, but a generic SOIC-16 breakout board could be used. Just make sure the board supports a 0.3" width device.

Next, remove the crystal and associated loading capacitors. The traces on the PCB are very fragile, so remove the components with care.

Connect the DS32KHZ as follows. The Sony PCB locations are from the silkscreen on the ICF-C1 clock PCB (image below).

Here is a picture of the installed DS32KHZ board. If you physically install the time base board at this location, the board will be clear of any obstructions inside of the case. I recommend using wire wrap (Kynar) 30ga wire to avoid lifting PCB traces that might happen with heavier gauge wire.

Here is the location of component changes to be made. After the load capacitor closest to the MCU has been removed, the DS32KHZS clock out can be soldered to the capacitor pad (the pad that connects to the MCU pin 12).

Great job, too much for my 80 year old eyes and patience. I hope Sony realizes their folly in using low cost crystals. I would gladly pay the extra cost.

ReplyDeleteThanks for the comment. Aging and then stepping up factory calibration would also help even with the crystal supplied, but the ultimate solution would be to derive the clock frequency from the powerline. My solution would bankrupt Sony!

DeleteOn the ifixit page where you mention this project there is a comment that says:

ReplyDelete"I have a SONY Dream machine ICF-C414 that also runs fast (but I have another, bit older ICFC180 and that one doesnt drift at all even after a year+.) ...."

Is the ICF-C180 fundamentally different in design to allow for more accuracy or might it be due to user error or chip variance?

I could not find any schematics for the ICF-C180 online to confirm, but I did find one for the ICF-C135. It uses an LM8560N clock radio IC, and if that IC is used in the ICF-C180 then yes, it is a fundamentally different design. The LM8560N internal counters use the powerline frequency (50Hz or 60Hz) and not a crystal. This approach is quite accurate day to day.

ReplyDelete